A Brief Story of Leather | History, Types, Functions & Alternatives

Reading Time: about

The leather industry is one of the oldest in the history of mankind. Our most distant ancestors used skins to protect their bodies, hands and feet. Leather is made from the skin of any mammal, reptile, bird or fish through a process called tanning. This process preserves the skin that would otherwise putrefy quickly.

Today, at least half of the leather produced is used for shoes and about a quarter for clothing. Only about 15% is used for furniture and the rest is processed into leather goods and other consumer products.

The hides and skins came from animals that were hunted or raised for food purposes. The current trend is for most upholstery leather to be derived from bovine hides (i.e. cowhide) as these are readily available and better suited to the needs of today's designers, producers and customers.

Far from losing its popularity, leather is still the material of choice for many people, not only for commercial and private furnishings, but also for the automotive, aviation and marine industries.

It's time to dive a little deeper into the history of this noble material: are you ready?

Summary

- 1. The History of Leather: Back to its origins

- Leather, one of the oldest human artifacts

- The leather industrialisation started as early as the Antiquity

- Leather from the Renaissance to the Modern Age: a revolution in manufacturing techniques and uses

- 1. The different natural characteristics and functions of leather

- The natural characteristic of leather

- The different fonctions of leather

- The different leather types

- 1. The different stages of leather manufacturing

- 1. Alternatives to authentic leather

- 1. Wrapping up

I. The History of Leather: Back to its origins

A. Leather, one of the oldest human artifacts...

Leather processing is an activity that goes back to the dawn of time. In prehistoric times, man sought protection from the weather and realized that the animals he ate were not only a source of food, but could also be used to make clothing or huts.

However, untreated skin takes very little time to putrefy. It was therefore necessary to find ways to preserve these skins so that they could be worn longer without filthy odors.

Researchers have shown that the earliest evidence of leather work, including the scraping of hides, dates back about 400,000 years (The oldest tools discovered to this day date from 84,000 to 72,000 years ago, and were discovered in South Africa).

📷 Credit: National Geographic's Youtube Channel

At that time, the Neanderthal man had his body covered with hair and didn't need clothes. However, he got into the habit of taking the skin from the game he had just killed in order to use it as an umbrella or sunshade.

These hides were placed on branches and taken away during hunting periods. The life span of these skins was short because of alternating rains and sunshine.

But around the year 8000 BC, a deluge occurred creating a turmoil characterized by the appearance of seasons more pronounced than during the Upper Paleolithic. The alternation of rain and sunshine became more and more frequent. Then the cold became more important, which pushed the man to cover himself to sleep.

In addition to this, man's genetic modification began to cause him to lose his abundant hair. And soon his skin needs protection. To meet this need, he hunted more and more and tried to increase the life span of his skins.

The first preservative was salt (also used to preserve meat), which humans of that time used to penetrate the raw hide (this preservation lasted until it rained). In order to prolong the preservation, humans got into the habit of degreasing the hides with clay before putting the salt in.

First trial of oil tanning appeared during the Neolithic period: the fatty acids in the oil interacted with the protein in the skin and made the product chemically stable. Most often, before coating the skin with brain, the skin was chewed, with the slightly acidic saliva acting as tannin.

Numerous historian argues that leatherwork was invented by chance. It is not known how long ago vegetable tanning was invented, but it is assumed that its discovery was largely a matter of chance.

According to the books of the Hittites, it was around 2200 BC that a shepherd from Sinai slaughtered a goat, took off the skin and defatted it with clay and salt. The goat was then carried away by a whirlwind in the distance.

It then fell back into a rock hollow filled with water which had partly dissolved alum salts. The presence of salt on the skin favored the action of the alum. Our shepherd a month later with his flock passed by the rock hollow where his skin had fallen. He saw it, picked it up, dried it again and put it on.

Contrary to usual times, the skin turned white but did not rot. Intrigued, the shepherd repeated the operation under the same circumstances and once again the skin stopped decomposing. He understood that the water in this place had peculiarities and that it was loaded with salt, which he called "Rock Salt". Our shepherd had become the first tanner in history.

The Hittites were a merchant people who had made it their specialty to sell their products from one region to another with caravans. For almost 1,000 years the Hittites were the only ones who knew how to tan leather and their prosperity was largely based on this secret.

📷 Credit: Epimetheus's Youtube Channel

It was around the year 2000 BC that a new technique of preservation using smoke appeared. Smoking was used by humans to preserve meat ("smoked meat"). They noticed that the skins worn during the smoking process became more resistant (we know today that the burning of green wood, leaves and bark releases tar-laden gases that settle in the hides and ensure sufficient preservation).

From the year 1000 B.C., in Central Europe they improved the technique. From the smoking, they improved the technique by rubbing the hides with birch bark to which they then added birch oil which gave "Russian Leather" with a very characteristic smell.

The Carthaginians were the first to break through the secret of tanning and adapt it to sheepskin. Around the year 1000 BC they established a large production centre for sheep hides in the Rhone delta near Marseille. One can therefore imagine that it was at this time that the first leather cases appeared. Then the descendants of the Hittites moved to Italy.

But with the Gallo-Roman wars, exchanges between the different regions were increasingly limited and little by little leather work began to decline.

B. The leather industrialisation started as early as the Antiquity

The Greeks and Romans had industrialized manufacturing techniques. The hides were soaked in large vats in which a solution of tannin was found.

In Rome, urine was used. It was collected in public toilets for artisan tanners. This trade was taxed by Vespasian who worked to generalize this public service. The Romans were the first people to use leather for both footwear and clothing and for the manufacture of shields and harnesses, outfitting hundreds of thousands of soldiers throughout Europe.

A tannery was excavated under the ashes of Pompeii. Archaeologists have found there many amphorae of Lipari. This island was known as a producer of tannin, the main advantage of which was, after treatment, to allow the product to be finished by dyeing. The tannin of Lipari was abundantly exported to Gaul.

In Spain, too, there are many traces of a thriving leather industry. Then under Moorish domination (around the 8th century), Cordovan leather production developed, notably thanks to innovations in tanning techniques. This leather was later sold all over Europe, particularly recognized for its quality and robustness.

In the Middle Ages, the leather working industry was organised and established in specific areas. Access to the hides had to be easy and the workshop had to be close to a river.

The 12th century can be considered as the century of the leather renaissance, as technological advances were significant. They were so consequent that between the 12th and 20th centuries, these techniques persisted without undergoing major changes. The large leather-working areas have remained the same for more than 8 centuries. It was not until the chemical industry developed in the 19th century that the leather industry was able to take advantage of this.

Most of the advances in leather working were, at the beginning, accidental and acquired through experience and observation. Later, the leather industry developed from small family productions to an industry located in hunting and breeding areas.

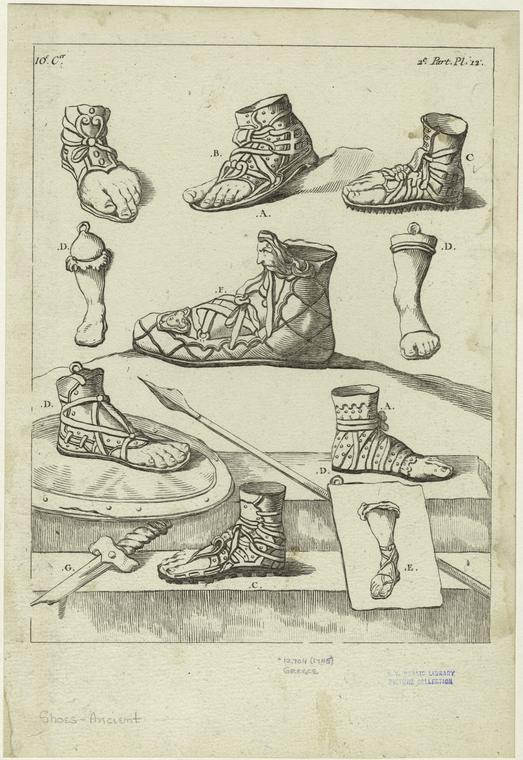

The Miriam and Ira D. Wallach Division of Art, Prints and Photographs: Picture Collection, The New York Public Library. (1784 - 1785).Various Footwear, Ancient Greece.Retrieved from http://digitalcollections.nypl.org/items/510d47e1-3319-a3d9-e040-e00a18064a99

C. Leather from the Renaissance to the Modern Age: a revolution in manufacturing techniques and uses

In the 16th and 17th centuries, the leather trades took on considerable importance and the profession was very prosperous. In France, there were more than 5,000 tanning workshops, employing between 30,000 and 40,000 people. Each city or town then has one or more tanning mills to make bark powder for vegetable tanning and a tannery.

At that time, leather was the only material that was both supple and resistant. Its use was very frequent and was used in the composition of many objects. However, production by natural tanning remained slow, with rudimentary tools. In a normal cycle it took several months to get a properly tanned leather.

The first extraction processes (chemical separation process) were experimented by renowned chemists such as M. Seguin under the direction of the Leather Convention in the 18th century. But it was not a success!

A great decline for the leather market occurs with the arrival of a new synthetic material: Plastic and its derivatives from oil.

This material made its appearance around 1870. The advantages of plastic are obvious: a very fast manufacturing time and a much lower production cost. The profession had to find a new manufacturing method to restore leather to its former place. In 1850, the German chemist Knapp discovered chrome tanning.

The first industrial production of leather with mineral tanning in France will take place in 1870. Machines to accelerate the chrome tanning process appear around 1880. At the beginning of the 20th century, the leather industry in France is considered to be the third largest after metallurgy and textiles.

Some technical improvements and new machines are noted at the beginning of the 20th century, but these advances remain very limited. The manufacturing cycle is still too long and takes several months.

From 1950 onwards, modern processes replace the old methods with an increase in production and the diversity of the leathers manufactured. The vast majority of leather companies enter the industrial sector.

The leather industry thus benefits from the appearance of synthetic polymers thanks to the development of chemistry, but also from considerable progress in tanning equipment. The leather market can thus follow fashion, and supply leathers of increasingly varied aspects: natural, waxed or modern with a wide range of reflections. New types of hides are also being tanned: reptiles, birds and fish!

At the same time, a general awareness of the environment intensified from 1970 onwards. Vegetable tanning remained constant and a new method of chrome tanning replaced significantly the old process, especially for uses such as shoe uppers.

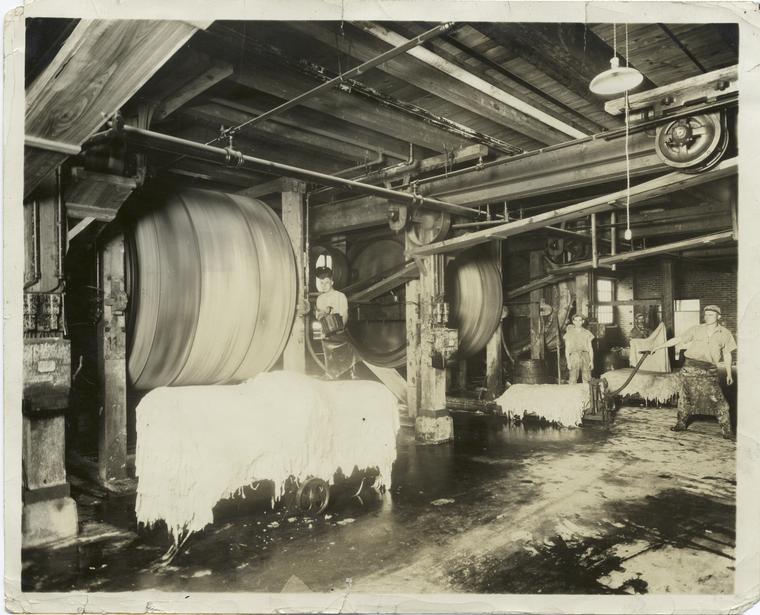

The Miriam and Ira D. Wallach Division of Art, Prints and Photographs: Photography Collection, The New York Public Library. (1860 - 1920).>Tanning Drums for Chrome Leather.Retrieved from http://digitalcollections.nypl.org/items/510d47d9-ad41-a3d9-e040-e00a18064a99

II. The different natural characteristics and functions of leather

A. The natural characteristic of leather

Leather in general is a natural product. It breathes, it warms, and has characteristics that make each skin unique. Leather will always bear the marks of its natural origin, and these characteristics can manifest themselves in the form of scars, growth marks, areas with dense fibres or uneven pore structure. These marks in no way compromise the quality of the leather. They are signs that discerning buyers appreciate when buying leather. With time and use, leather develops a patina that emphasizes its beauty.

1. Veins and growth marks

These are indications of the age of the animal and as such are similar to the wire on a piece of wood. They can range from very pronounced markings in the neck area to very subtle stripes across the skin, perpendicular to the line on the back. The most pronounced growth marks are often placed on the back of the seat backs.

2. Scars

They are usually formed by contact with barbed wire or by the horns of another animal. When these marks are healed, the new dermis is as solid as the rest of the skin, but if they are not healed they should be rejected because tension on this part of the skin can create a tear.

3. Variations in skin texture

The texture of the fibre varies a lot, from loose in the belly area, it becomes taut on the spine. The looser areas therefore have more lending. Variations in pore structure are particularly noticeable on natural grain leathers, on which enlarged pore aggregates are sometimes observed.

4. Color variations

Each skin is unique; and because of the different skin grains mentioned above, dyes and finishes penetrate each part of the skin differently, giving it elegant shades. While we strive to maintain uniformity, this is not always possible and not necessarily desirable.

B. The different fonctions of leather

1. Protection against the cold

Researchers estimate that the first treated skins date back to 17,000 BC. At that time, hominids used flint and shells to treat their skins.

Although rustic, this treatment allowed them to protect themselves from the cold. Furs were particularly appreciated and allowed them to get through the coldest winters. It was only later that traces of more sophisticated tools were found.

This function is still important today, especially in the clothing industry, where the waterproof capabilities of leather allow jackets to retain body heat (in addition to protecting against moisture).

2. Distinction and Ornament

Leather was also a mark of power. The greatest chefs wore the rarest leathers. Thus, it was not uncommon to let animal distinctions appear on the hides (fangs, paws, mouth, etc.). In this way, men appropriated the animal's strengths and peculiarities. The most beautiful skins represented offerings or gifts (to chiefs or gods).

This function is also still relevant today, especially in the luxury sector where the most beautiful leathers adorn designers' creations. Leather is an extremely noble material because it is resistant and pleasant to the touch. It is found in many luxury creations, and through many industries (textile, interior design, automotive).

3. Leather as a commodity

It was much later, with the improvement of the treatment of hides, that leather became a real commodity. It was highly prized by the Romans and was a formidable armor and a pleasant garment.

The first tanners, true craftsmen of another era, were born at this time. Since then, tanning has continued to progress until it became what it is today.

C. The different leather types

Leather is often associated with cows, as it is one of the most common leathers. However, the term leather covers the use of the hide of many animals. Similarly, depending on the working method used, leather is given different names

a. Types of leather according to their origin

- Lambskin leather: smooth and delicate leather, it is used for clothing and gloves for its fineness and suppleness.

- Sheep leather : Thicker than lamb, with a more pronounced grain and a lower price, it is mainly used for clothing.

- Goat's leather : it is a very resistant leather despite its fineness and its grain is slightly grainy. Relatively cheap, it is mainly used for jackets.

- Pig leather: it is a thick, very resistant, porous and naturally light leather. Cheap, it is used to make jackets.

- Calf leather: Calf leather (Box calf) is a noble, smooth and supple leather, used in luxury leather goods for bags and top-of-the-range shoes.

- Buffalo leather: naturally grained and supple, it is one of the most resistant leathers often used for men's clothing and the manufacture of laces of top-of-the-range leathers.

- Suede: This is a supple leather used in the manufacture of clothing, gloves and shoes.

- Cowhide: This is a smooth and thick cowhide leather with a smooth and shiny grain. Widely used because of an abundant raw material derived from human food waste.

- Deer leather: Used mainly in glove-making, this leather has a coarse grain.

- Ostrich leather : Used in luxury leather goods, ostrich leather is supple and has a very particular grain.

- Peccary leather : This leather comes from a wild pig from South America, which has the advantage of having a very fine and resistant skin. It is used in glove-making and luxury leather goods and tends to disappear due to the disappearance of the animal in its natural environment.

- Antelope leather: Soft and fine leather, little used and quite expensive.

- Shagreen : Shagreen is a leather obtained from stingrays of different species. Tanned with chrome, and after sanding the pointed scales, shagreen is increasingly used in the manufacture of handbags and watch straps.

- Tilapia leather: Tilapia is a tropical fish, of African origin, giving fine leathers that are still little used.

- Shark leather: it is a rare leather, waterproof, rigid and resistant. This top-of-the-range leather is used in the manufacture of shoes, in leather goods and in bookbinding.

- Sea bass leather : gives a leather from 0.7 to 0.9 mm, very soft, supple and without scales.

- Reptile leather: crocodiles, alligators, lizards, cobras, python: these are top-of-the-range and very expensive leathers used in small leather goods and in the manufacture of boots.

- Frog or toad leather: A rough and swollen leather for the toad, smooth, fine and fragile for the frog leather. These leathers are relatively little used.

📷 Credit: Pink Again's Youtube Channel

b. Types of leather according to their processing techniques

- The morocco: it is a goat or sheep leather tanned with sumac extract (Plant of Moroccan origin).

- Russian leather : it is a leather tanned with birch bark which improves its resistance to humidity and mould.

- Boiled leather: it is a leather boiled in water, giving it a certain hardness.

- Wrought leather: this is leather that has been immersed in water and treaded and coated with oil to make it supple and waterproof.

- Nubuck: this is a leather whose surface has been scraped on the grain side to give it a velvety appearance.

- Suede: not to be confused with nubuck or the leather originating from the animal, suede leather has been scraped on the crust side to make it look like nubuck. It is of course much cheaper than nubuck because suede leather is made from split leather.

- Box calf: This is a high quality calf leather tanned with chrome, with a smooth aspect, used in luxury leather goods.

- Aged leather: This is a leather that has been tumbled in a drum to give it a cracked finish.

- Immersed leather: this is leather that has been dyed in the mass by immersion in a dye.

- Oily leather : it is a leather that has been immersed in oil to give it suppleness, resistance and waterproofing. It is widely used for the manufacture of leather hats and jackets.

- The crust : it is a natural leather without finishing.

- Vegetable leather: it is a leather tanned from vegetable extracts and not from chrome. This treatment is longer and more expensive.

- Nappa leather: This is a full-grain leather treated to make it very supple and waterproof. The top-of-the-range leather thus obtained is fine, smooth and grain-free.

- Double-sided leather: Also called woolly hide, this is a sheep or lambskin leather in which the wool is preserved.

- Full grain leather: this is a leather made with the upper part of the hide, the noblest part.

- Leather crust: This is the lower part of the hide, the least noble and the cheapest.

📷 Credit: Boss Leather's Youtube Channel

III. The different stages of leather manufacturing

1. Salt action

Fresh skins are salted to remove water from the tissues and thus slow down the degradation caused by the development of the microorganisms present: coarse miner's salt with a grain size of 2 to 3 mm in diameter is used and antiseptic agents may be added. During salting, skins can lose up to 10% of their weight in water. The hides are stacked in such a way as to facilitate the flow of brine in a room with a relative humidity of 70 % to 90 %. The temperature is maintained at around 10 °C to improve the preservation of the hides.

After 15 days, the hides are desalted, examined one by one and sorted according to thickness, number of skin defects, presence of scars, weight and surface area.

2. River work

Once the hide arrives at the tannery, it undergoes the "river work" which is a succession of five operations:

- Soaking (or rewetting): the skin is re-moistened to remove impurities and stains;

- Depilation/peeling: this operation consists of the chemical removal of hair and epidermis thanks to the pelain;

- Fleshing: at this stage, the subcutaneous tissue is removed mechanically with a fleshing machine;

- Confiting: elastin is eliminated thanks to enzymes which will also finish cleaning the surface of the skins;

- Pickling: at this stage, the skins are still putrescible, to prepare them for the tanning stage or to preserve them, they are acidified and salted to remove them from the water.

3. Vegetable tanning

In this process the skin is treated with vegetable tannins extracted from the bark and wood of certain trees. For centuries, oak bark has been used as a source of tannin, but today mimosa tannin, extracted from the bark of different varieties of mimosa, is more common. Vegetable tanning is traditionally carried out in pits: the skins are hung in a series of pits or vats filled with a tanning solution that becomes stronger every day. This process is slow and can take several weeks or even months before the hides are fully tanned. This method is now rarely used in the production of upholstery leather. More modern, more scientifically controlled processes are borrowed, using drums in the later stages of the process to speed it up.

3bis. Mineral tanning

This tanning is usually carried out using basic chromium sulphate, a mineral salt that penetrates very quickly into the hide, thus completing the tanning process within twenty-four hours. The leather is then a light/pale duck blue, and after appropriate treatments will become a modern soft leather of high quality. Other mineral tannings (e.g. alum) are also used.

Aldehyde tanning refers to the use of chemicals such as glutaraldehyde or oxazolidine. It is a sought-after type of leather, especially in the children's clothing industry because it is the only leather that does not contain chromium, which is potentially harmful to health.

4. Corroyage

Once tanned, the leather still needs to undergo further treatment before it can be marketed. It undergoes :

- Spinning: to remove a quantity of water from the tanned hides to be able to handle the leather;

- Sorting: the hides are classified according to surface defects

- Splitting and shaving: the leather is thinned to obtain the desired thickness;

- Retanning / Dyeing / Fodder: the leather is reworked according to its final use: fit, density, colour and suppleness are adjusted;

- Spinning - Wind-drying: allows to have flat leathers;

- Drying: step to obtain a dry leather;

- Furling: allows to soften leathers.

5. Finishing

At this stage, the leather will acquire specific properties, notably on texture and appearance. These properties make it possible to standardize the leathers produced. Depending on the use, a distinction is made between aniline, semi-aniline and pigmented finishing.

The aniline finish enhances the surface of the leather by covering it with a transparent product. It is a leather that looks very nice, but requires special care.

Semi-aniline leather is covered with a layer of slightly opaque pigment and a layer of translucent product, which makes it possible to hide small defects.

Pigmented leather is only covered with an opaque pigment layer. It is easy to care for and not very sensitive to water.

📷 Credit: pellevegetale's Youtube Channel

IV. Alternatives to authentic leather

A. Artificial Leather Alternatives: Synthetic Leather

Synthetic leather, also known as faux leather, is a leather-like plastic material, usually made of non-woven fibres (mostly polyamide), trapped in a resin such as polyurethane. It does not contain any animal fibres. It should not be confused with polyurethane leather or PU leather which is a leather (damaged hides or hide waste) agglomerated with synthetic polymers and imitating real leather or By-Cast leather which is a crust of leather covered with a polyurethane film reproducing the surface of the leather.Synthetic leather is used in many articles (shoes, key rings, cases...) because of its aesthetic appearance, its resistance to external aggressions and above all its low price compared to leather.This plastic material does not have the right to be called "leather".

📷 Credit: BTODtv's Youtube Channel

B. Natural Lather Alternatives

To start with the most famous alternative to animal leather: there is pineapple leather, or Piñatex, a waterproof and strong fabric that looks like leather, can be dyed and can be obtained in different textures and thicknesses.Made from fibres extracted from pineapple leaves, it is inexpensive and environmentally friendly, being made from recovered material. Having been excellently received at the Royal College of Art in London, Piñatex has even attracted major brands such as Puma and Camper, who are developing prototypes of their shoes made from this material.

Other fruits are used to replace the leather, and in the case of Fruitleather, these are the unsold fruits that would otherwise be discarded. Design students in the Netherlands have developed prototype bags made of nectarine skin and mango, by cooking, crushing and dehydrating kilos of fruit to obtain a durable, odourless, plant-based textile that can have different textures and properties.

Vine leather is also a newcomer - made from the residues of skins, stems and seeds from grape exploitation - as is MuSkin (leather made from mushroom skin), rubber tree leather (made from latex, the sap of the rubber tree), and leather made from celluloses recovered from Kombucha tea. A Danish designer has also recently developed a biodegradable material made from apple pulp residues used in cider production, which is rigid and flexible and resembles leather - and is one of PETA UK's approved vegan manufacturers, along with MuSkin and Piñatex.

Cork, on the other hand, does not attempt to resemble leather, but can be used in similar ways (in Vans or Nike shoes, for example, or in bags and wallets, as evidenced by the Jentil brand). Natural, resistant and waterproof, cork is even more than environmentally friendly, with cork oaks capturing twice as much CO2 as any other tree.

📷 Credit: Piñatex by Ananas Anam's Youtube Channel

IV. Wrapping up

Leather is an ancient, robust and natural material. Its applications have multiplied over time and have even resisted, despite a sharp decline, the arrival of synthetic textiles.

Nowadays, leather is strongly criticized for its manufacturing conditions and environmental impact, but its durability makes it an undeniable asset for designing parts that will last over time.

Indeed, while the creation of a leather object has a greater environmental impact than another made of synthetic textiles, its durability over time more than compensates for this.

The important thing is to choose quality leathers, manufactured in compliance with standards in order to have a unique and robust product.

📫 Related Blog Posts:

📌 What is Split Leather? From History to Care Tips and Beyond

📌 Vegan Leather | A Realistic Alternative to Real Leather?

📌 What is Bonded Leather? A Controversial Alternative to Real Leather

📌 What are Aniline Leather & Semi-Aniline Leather?

📌 What is Shell Cordovan ? The Timeless Elegance of a Premium Leather

📌 What is Chamois Leather? Demystifying This Unique Material

📌 What is Tooling Leather? A Comprehensive Guide

📌 What is Full Grain Leather? History, Craftsmanship & Timeless Appeal

📌 How to Get Wrinkles Out of Leather? Bring Your Leather Back to Life

1 comment

how will they get actual pelt

Leave a comment