What is Nylon? The Revolutionary Material Shaping Our World

Reading Time: about

Dive into the fascinating universe of nylon, a marvel of modern science that weaves itself seamlessly into our daily lives. Imagine a material so versatile that it transcends the boundaries of fashion, industry, and technology.

You see, nylon isn't just another material; it's a revolutionary creation that has transformed industries and lifestyles since its inception. In this article, we'll explore what nylon really is, how it's made, and its myriad applications. We're talking about a journey from science labs to your very own backpacks and stockings!

Now, you might be wondering: Is nylon natural or synthetic? How does it hold up against its arch-nemesis, polyester? Is it eco-friendly, or are we talking villain-level environmental impact here? And, of course, the real tea: can you shrink it, stretch it, dye it, iron it without causing a domestic disaster?

We'll answer all these questions and more, keeping things light, simple, and to the point. Think of this as your one-stop guide to understanding nylon, whether you're a fashion enthusiast, a curious student, or just someone who accidentally shrunk their favorite nylon shirt (we've all been there). So, let's unravel the nylon story together, one thread at a time! 🧵✨

Summary

- 1. What is Nylon?

- 2. How is Nylon Made?

- 3. Is Nylon Natural or Synthetic?

- 4. Is Nylon Toxic?

- 5. What is The Difference Between Nylon and Polyester?

- 6. Is Nylon Waterproof or Water-resistant?

- 7. Does Nylon Shrink?

- 8. Is Nylon Breathable?

- 9. Is Nylon Stretchy?

- 10. How to Care for Nylon?

- 11. What is Nylon Used For?

- 12. FAQ

I. What is Nylon?

So, what exactly is this nylon we keep talking about? Imagine a material that's strong like Hercules, flexible like a gymnast, and more versatile than a Swiss Army knife. That's nylon for you - a synthetic polymer that's become a superstar in the world of fabrics and plastics.

1. Historical Background

Let's hop into our time machine and rewind to the 1930s. The stage is set at the famous DuPont laboratories, where a brilliant team of chemists, led by the legendary Wallace Carothers, is about to change the world. They were on a mission to create a fiber that could rival silk, and boy, did they succeed! In 1935, they introduced nylon, marking the birth of the world's first true synthetic fiber.

Key milestones? Well, nylon made a grand debut in 1938 at the New York World's Fair, touted as the fiber that could do it all. Then came the iconic moment in 1940 when nylon stockings hit the market, causing a shopping frenzy like no other. Believe it or not, these stockings were such a hit that they even caused minor riots!

2. Chemical Composition

Now, let's put on our lab coats and take a closer look at what nylon is made of. At its core, nylon is a type of plastic derived from petrochemicals. It's a polyamide, which means it's made up of repeating units linked by amide bonds. Think of it as a long chain of molecules, all holding hands in a line.

But here's where it gets interesting. Unlike natural fibers like cotton or wool, nylon's structure is entirely man-made, crafted through a process called polymerization. This is where the magic happens: smaller molecules called monomers join forces to create a super strong and durable polymer chain.

3. Comparison with Other Synthetic Fibers

Now, you might be thinking, "Isn't that similar to other synthetic fibers?" Well, yes and no. Take acrylic and rayon, for example. While they're also synthetic, they have different superpowers. Acrylic is like nylon's cozy cousin, known for its wool-like warmth and softness. Rayon, on the other hand, is the smooth operator, mimicking the feel of silk.

But here's where nylon shines - it's exceptionally strong and resilient. It's like the superhero of synthetic fibers, boasting superior abrasion resistance and toughness. So, whether you're scaling a mountain or just running to catch the bus, nylon's got your back!

4. The Different Types of Nylon

Nylon, often hailed as a miracle fiber, is not a one-size-fits-all material. It comes in various forms, each with unique properties and applications. Let's explore the diverse world of nylon types and what makes each one special.

1. Nylon 6,6

- Structure: Nylon 6,6 is one of the most common types of nylon. It's made from two monomers, each containing six carbon atoms, hence the name 6,6.

- Properties: This type is known for its high melting point, excellent wear resistance, and superior strength.

- Uses: Commonly used in carpet fibers, tire cords, and ropes.

2. Nylon 6

- Structure: Unlike Nylon 6,6, Nylon 6 is formed from a single type of monomer with six carbon atoms.

- Properties: It's more pliable and has a lower melting point compared to Nylon 6,6, but still maintains high tensile strength.

- Uses: Widely used in clothing, industrial yarns, and plastic components for vehicles.

3. Nylon 11 and Nylon 12

- Structure: These are made from monomers containing 11 and 12 carbon atoms, respectively.

- Properties: They are more flexible and have better impact resistance and moisture absorption properties than the shorter chain nylons.

- Uses: Ideal for use in tubing, hoses, and in some cases, in 3D printing materials.

4. Nylon 4,6

- Structure: Made from two different monomers, with four and six carbon atoms.

- Properties: It has a higher melting point and better heat resistance than Nylon 6,6.

- Uses: Often used in high-temperature automotive applications and as a material for specialty coatings.

5. Nylon 6,10 and Nylon 6,12

- Structure: These nylons are synthesized from different monomers, leading to longer molecular chains.

- Properties: They offer lower moisture absorption compared to Nylon 6, making them more stable in varied environmental conditions.

- Uses: Common in tubing, filaments, and in some industrial applications.

6. Bio-Based Nylons

- Structure: These are relatively new and are made from renewable sources like vegetable oil.

- Properties: They have a similar performance to traditional nylon but with a smaller environmental footprint.

- Uses: Gaining popularity in environmentally conscious industries and consumer products.

Each type of nylon brings its own set of characteristics to the table, making the material incredibly versatile. From the clothes we wear to the cars we drive, nylons of various types play an integral role.

In our next section, we'll dive into the intriguing process of how nylon is made. Spoiler alert: it's like a fascinating science experiment you don't want to miss! 🧪👩🔬👨🔬

📷 Credit: NBC News Learn's Youtube Channel

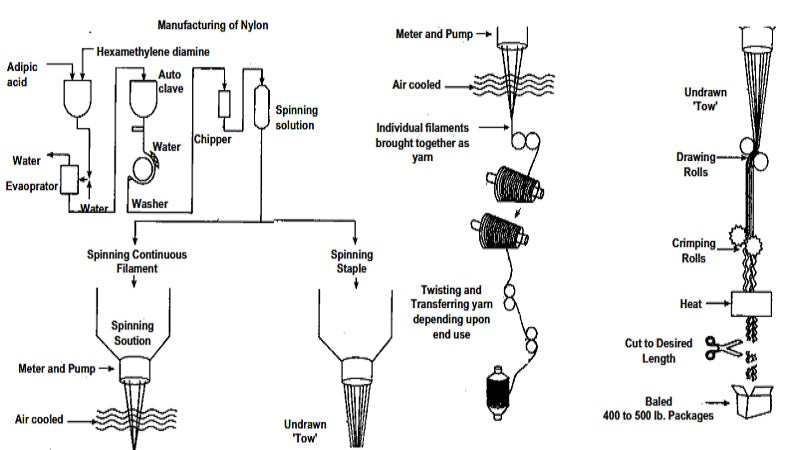

II. How is Nylon Made?

Alright, let's roll up our sleeves and get into the nitty-gritty of how nylon is actually made. Think of it as a culinary adventure, but instead of whipping up a gourmet meal, we're cooking up a groundbreaking synthetic fiber!

1. Production Process

The creation of nylon is a classic example of polymerization, a process that might remind you of building a Lego tower, one block at a time. But instead of Lego, we have molecules called monomers, and when they link up, they form a polymer, which in our case, is nylon.

Here's the technical bit: There are two main methods to produce nylon - condensation polymerization and addition polymerization. In condensation polymerization, the process starts with two different types of monomers. When they react, they bond together and release a small molecule, usually water. This is like a molecular tango, where each step (or reaction) creates a longer and stronger chain.

In addition polymerization, the monomers just keep adding to the chain, one after the other, without releasing any other molecule. This is more like a conga line of molecules that keeps getting longer and longer.

2. Industrial Methods and Technologies

In the world of industrial nylon production, things get pretty high-tech. Manufacturers use specialized reactors where the magic of polymerization happens. Temperature and pressure are meticulously controlled to ensure the nylon that comes out is just perfect - strong, durable, and ready for action.

One of the most common forms of nylon produced is Nylon 6,6. It's made by reacting adipic acid with hexamethylene diamine, two substances that sound like they belong in a sci-fi movie but are actually quite common in the chemical industry.

3. Raw Materials

Speaking of these materials, let's talk about the raw ingredients for our nylon recipe. Adipic acid and hexamethylene diamine are the key players. They are derived from petrochemicals, which, in simpler terms, means they come from crude oil.

Sourcing these materials is a major part of the nylon production process. Since they're derived from non-renewable resources (hello, crude oil!), there's a significant environmental footprint involved. The extraction, refining, and processing of these petrochemicals require a lot of energy and can lead to greenhouse gas emissions.

But wait, it's not all doom and gloom. The industry is constantly evolving, and there's a growing push towards more sustainable practices. This includes exploring bio-based alternatives for these raw materials and finding more energy-efficient production methods.

So, while nylon's journey from petrochemicals to your favorite jacket or backpack might not be as simple as spinning a fairy tale yarn, it's a tale of science, innovation, and a bit of environmental awareness. Stay tuned for the next chapter, where we'll unravel the mysteries of whether nylon is a friend or foe to Mother Nature! 🌍🔬🌿

📷 Credit: NileRed's Youtube Channel

III. Is Nylon Natural or Synthetic?

Now, let's address a question that often pops up: Is nylon a natural marvel or a synthetic sensation? Spoiler alert: It's the latter. But let's dig deeper to understand why.

1. Defining Synthetic Materials

First things first, what makes a material synthetic? In the simplest terms, synthetic materials are those not found in nature but created by human ingenuity and chemistry. They're like the science fiction of the material world – born in a lab, not in nature.

The criteria for classifying a material as synthetic include:

- Human-Made Origin: Synthetic materials are concocted from chemical substances and typically do not exist in the natural world.

- Chemical Process: They're produced through chemical processes that transform basic raw materials into polymers with unique properties.

- Reproducibility: Unlike natural materials, which can vary based on environmental conditions, synthetics can be consistently replicated in a controlled setting.

2. Overview of Synthetic Fiber Industry

The synthetic fiber industry is like a bustling city of innovation. It's home to materials that revolutionize how we dress, furnish our homes, and even how we play sports. From polyester to acrylic, this industry has created a smorgasbord of materials that cater to various needs – durability, elasticity, resistance to water, you name it.

a. Nylon's Classification

Now, back to nylon. Why is it classified as synthetic? Nylon was the first fabric made entirely in a lab. Its creation involves a complex chemical process where organic compounds (those monomers we talked about) are transformed into a long chain of polymers – a process not found in the natural world. This classifies nylon as a synthetic polymer, distinct from naturally occurring fibers.

b. Comparison with Natural Fibers

When nylon is put side by side with natural fibers like cotton or silk, the differences become pretty clear. Cotton, for instance, is harvested from cotton plants, and silk is a protein fiber produced by silkworms. They're part of nature's inventory, grown and harvested, not cooked up in a lab.

Nylon, on the other hand, comes from a more industrial birthplace. It's engineered to have specific qualities – strength, elasticity, and resistance to wear and tear – that are consistently replicable, unlike the natural variances you find in cotton and silk.

Nylon, a synthetic powerhouse, born from human ingenuity and chemical wizardry. In our next segment, we'll tackle the big question: Is nylon safe, or does it hide a toxic secret? Stay tuned to find out! 🌐🔍👩🔬🧪

IV. Is Nylon Toxic?

Now, let's tackle a topic that's as important as it is complex: the safety and environmental impact of nylon. Is it a silent villain, or is it as harmless as your average superhero sidekick? Let's break it down.

1. Chemical Safety

When it comes to chemical safety, nylon throws a bit of a curveball. During its production, certain chemicals and gases are released, some of which can be harmful if not managed properly. But here's the catch: once nylon is made, it becomes a pretty stable and inert material. This means that the final nylon product you use in your clothes or gear doesn't just start releasing toxins willy-nilly.

However, during the production phase, workers can be exposed to chemicals like caprolactam, particularly when manufacturing Nylon 6. While caprolactam can be irritating to the skin and eyes, modern manufacturing processes are designed to minimize such risks. It's all about safe handling and proper industrial practices.

Health Concerns

What about when you wear nylon? Does it pose any health risks? Generally, nylon is considered safe for most people. There's no evidence suggesting that wearing nylon causes any significant health issues. However, some people might experience allergic reactions or skin irritation, especially if they're sensitive to synthetic fabrics. But let's be clear: this is more of a 'your mileage may vary' situation than a broad, sweeping health hazard.

2. Environmental Impact

Now, let's talk environment – because, let's face it, we all want to keep our planet green and gorgeous. Nylon's environmental footprint is, well, complicated. On the one hand, producing nylon is resource-intensive, requiring significant amounts of water and energy. The process also emits nitrous oxide, a potent greenhouse gas.

On the flip side, nylon's durability means products made from it tend to last longer, potentially reducing waste in the long run. But there's a catch: When nylon products finally do reach the end of their life, they don't biodegrade easily, contributing to landfill issues.

Recycling and Sustainability Initiatives

The silver lining? The industry is buzzing with efforts to make nylon more planet-friendly. Recycling nylon has become a hot topic, with initiatives to repurpose everything from old fishing nets to fabric scraps. This not only reduces waste but also cuts down on the need for new raw materials.

Moreover, there's a growing interest in developing bio-based nylons – think nylon made from renewable resources like plant oils. These innovations aim to reduce the reliance on petrochemicals and lower the overall environmental impact.

So, is nylon toxic? The short answer: not in its final form, but its production and disposal raise some environmental eyebrows. As we stride forward, the focus is on making nylon safer and more sustainable – because who doesn't love a material that's both strong and kind to Mother Earth? 🌍💚🔬

📷 Credit: Montreal Gazette's Youtube Channel

V. What is The Difference Between Nylon and Polyester?

When it comes to the great debate of nylon vs. polyester, it's like comparing two superheroes with different superpowers. Both have their unique strengths and uses, so let's dive into what sets them apart.

1. Composition Differences

First, let's talk chemistry. Nylon is a polyamide, formed by linking monomers with amide bonds. Imagine a chain where each link is a blend of carbon, hydrogen, oxygen, and nitrogen. On the other hand, polyester is a polyethylene terephthalate (PET), made by combining ethylene glycol and terephthalic acid. Its chain is more about carbon and oxygen.

These chemical distinctions lead to different physical properties. Nylon is typically softer, with a silkier feel, while polyester has a slightly rougher texture. Nylon's structure gives it excellent elasticity and resilience, whereas polyester is known for its high resistance to environmental conditions like UV rays and moisture.

Impact on Properties and Uses

These differences play out in various ways. Nylon's elasticity makes it ideal for products that need to stretch but retain their shape – think hosiery or backpack straps. Its resilience under tension and abrasion resistance also makes it great for heavy-duty applications like ropes and outdoor gear.

Polyester, with its resistance to UV and moisture, shines in outdoor and aquatic environments. It's often used for outdoor clothing, tents, and sails. Plus, its ability to retain dyes and resist fading is a big win for the fashion industry.

2. Performance Comparison

Now, let's compare their performance. In terms of strength, both are strong, but nylon has the edge in abrasion resistance and elasticity. Polyester, however, takes the crown for UV resistance and moisture wicking.

Comfort-wise, nylon's softness gives it a more natural feel, similar to cotton, making it a go-to for garments that are close to the skin. Polyester, while not as soft, excels in moisture management, making it a favorite for activewear and performance apparel.

Suitability for Different Applications

Choosing between nylon and polyester really boils down to the application. Need something for outdoor adventure gear? Nylon's toughness and flexibility might be your best bet. Looking for workout clothes or outdoor furniture covers? Polyester's moisture-wicking and UV-resistant properties might serve you better.

In summary, both nylon and polyester are champions in their own right. It's like choosing between Batman and Superman – each has their unique strengths and ideal scenarios where they shine the brightest. Whether you're scaling a mountain or running a marathon, there's a synthetic fiber out there tailored just for your needs! 🏞️🏃♀️🧗♂️🌞

📷 Credit: FittDesign Studio's Youtube Channel

VI. Is Nylon Waterproof or Water-resistant?

When it comes to battling the elements, understanding the water resistance of materials like nylon is key. But first, let's clear up a common mix-up: the difference between being waterproof and water-resistant.

1. Waterproof vs. Water-Resistant

In the world of fabrics, "waterproof" and "water-resistant" are often used interchangeably, but they're not the same. Waterproof materials provide a complete barrier against water - think of a raincoat that keeps you dry in a downpour. Water-resistant materials, however, can resist water penetration to some degree but not entirely. It's like having an umbrella that keeps you mostly dry during a light drizzle.

Enhancing Nylon's Water Resistance

Nylon, in its natural state, is water-resistant but not waterproof. It has a tendency to absorb some water, which can impact its strength and durability. However, we've got some clever tricks up our sleeve to boost its resistance.

One common method is coating or treating nylon with water-repellent chemicals. These treatments cover the fibers with a protective layer that repels water, rather than absorbing it. Another approach is laminating the nylon with layers of waterproof materials, creating a sandwich-like structure that water can't penetrate.

2. Nylon's Water Handling Properties

Let's talk behavior. When nylon gets wet, it absorbs a small amount of water. This can lead to a slight change in its properties, like reduced strength and elasticity. But don't worry, the change isn't drastic, and once it dries, nylon bounces back to its original state.

This water absorption can actually be a plus in some situations. For instance, in activewear, the absorbed moisture can provide a cooling effect, making it more comfortable to wear during a sweaty workout.

Comparison with Other Water-Resistant Materials

Compared to other materials, nylon holds its own quite well. It's more water-resistant than natural fibers like cotton but not quite as impenetrable as some synthetic counterparts like polyester or specially treated fabrics.

However, nylon's balance of water resistance, durability, and breathability makes it a popular choice for a wide range of applications, from raincoats to camping gear. It's about finding the right balance for the job – whether you need something for a light jog in the mist or a hardcore hike in the rain. 🌧️🏃♀️🏕️💦

📷 Credit: People·WHYS's Youtube Channel

VII. Does Nylon Shrink?

Ah, the age-old question: does nylon shrink? The answer is a bit like a suspense thriller – it's all about the conditions.

1. Nylon's Reaction to Heat

Here's the deal: nylon is somewhat of a drama queen when it comes to heat. Its scientific structure makes it sensitive to high temperatures. Think of nylon molecules as a tightly knit community. When they're exposed to heat, they tend to relax and spread out, just like people sunbathing. But, unlike us, once they cool down, they don't always return to their original tight-knit community.

So, yes, nylon can shrink, but it's not as straightforward as with natural fibers like cotton. It's more like nylon gets a little 'stressed out' by the heat and decides to tighten up. This is especially true when you wash it in hot water or, heaven forbid, toss it into a hot dryer.

Case Studies or Examples

Let's take a real-world scenario. Imagine two nylon garments: one goes through a gentle wash cycle with cool water, and the other takes a trip through a hot wash and an even hotter dryer. The first one comes out almost unchanged, but the second one? It might just fit your pet Chihuahua now!

2. Preventing and Managing Shrinkage

Now, onto the practical side of things. Want to keep your nylon gear in tip-top shape? Here are some golden rules for nylon laundry care:

- Cool It Down: Always wash nylon in cool or lukewarm water. Think of it as giving your nylon a relaxing spa day.

- Gentle Does It: Use a gentle cycle on your washing machine. Nylon is tough, but it appreciates a soft touch.

- Avoid the Heat: When drying, skip the hot tumble dryer. Instead, lay your nylon garments flat or hang them up to air dry. They'll thank you for it!

- Iron with Care: If you must iron nylon, use a low-heat setting and preferably place a cloth between the iron and the nylon. Think of it as a protective shield.

Long-term Maintenance Advice

To keep your nylon looking new for years to come, follow these tips:

- Regular Cleaning: Regular, gentle washes prevent buildup of dirt and oils.

- Storage Matters: Store nylon garments in a cool, dry place away from direct sunlight.

- Repairs: For snags or tears, seek professional repair or use nylon-specific repair kits.

So there you have it, the lowdown on nylon and heat. Treat it right, and it'll be a long-lasting companion in your wardrobe adventures. Next, let's take a closer look at nylon's breathability – crucial info for those of us who like to keep cool under pressure! 💨👕🧥

VIII. Is Nylon Breathable?

Now, let's talk about breathability - a big deal if you're into clothes that don't turn you into a walking sauna. When it comes to fabrics, breathability is like that cool breeze on a hot summer day; it's all about letting air in and out to keep you comfy.

1. Fabric Breathability

First things first, what makes a fabric breathable? It's all about the fabric's ability to allow moisture and air to pass through it. Imagine tiny invisible doors in the fabric that open and close to let your skin breathe. The size of these doors (or pores), the fabric's weave, and the material itself all play a part in how well a fabric can say 'hello' to fresh air and 'goodbye' to body sweat.

Factors like the thickness of the fabric, how tightly it's woven, and even the shape of the fibers can make or break a fabric's breathability. It's a delicate balance, like making the perfect cup of coffee - too much of one thing, and it's just not right.

Nylon's Air Flow Properties

So, where does nylon stand in the breathability league? Well, nylon has its pros and cons. It's like that friend who's great at sports but not so great at chilling. Nylon is a tight-knit character, literally. This means it's not the most breathable fabric out there. It's more like a barrier, keeping moisture in rather than letting it out. That's why nylon might not be your first choice for a marathon run in the Sahara.

But don't write nylon off just yet! It has its moments, especially when blended with other fabrics. When nylon is mixed with more breathable buddies like cotton or polyester, it learns to let loose and let the air flow. These blends offer the best of both worlds - durability and breathability.

2. Comparison with Breathable Fabrics

Now, let's compare nylon to the MVPs of breathability - cotton and linen. These natural fibers are like the cool kids of the fabric world. Cotton, with its airy structure, allows air to pass through easily, making it a go-to for hot weather. Linen takes it up a notch with its loosely woven fibers, making it feel like you're wearing your own personal breeze.

In contrast, nylon's tight-knit structure keeps air from moving freely, which can lead to a bit of a steamy situation. However, modern technology has given nylon a breath of fresh air. Advances in fabric technology have led to more breathable versions of nylon, making it a more comfortable choice than its ancestors.

So, there you have it - while nylon might not be the king of breathability, it's certainly working on its airflow game. In our next section, we'll explore the fascinating world of nylon's elasticity. Get ready to stretch your imagination! 🏃♂️💨👚

📷 Credit: FittDesign Studio's Youtube Channel

IX. Is Nylon Stretchy?

Alright, let's stretch our imaginations (pun intended) and delve into the world of elasticity in fabrics, focusing on our star player: nylon. Have you ever wondered why some fabrics can go from a size "oh no" to a size "oh wow" without tearing? Well, that's all thanks to their elasticity.

1. Elasticity in Fabrics

Elasticity, in textile science, is basically a fabric's ability to return to its original shape after being stretched or compressed. Think of it like a rubber band. You pull it, and it stretches; you let it go, and it bounces right back. Fabrics work in a similar way, thanks to their unique fiber structures and the way they're woven or knitted.

But what makes a fabric elastic? Several factors come into play here. The type of fiber is a big one. Then there's the fabric's structure – how the fibers are woven or knitted together. Even the finishing processes, like treating the fabric with certain chemicals, can affect elasticity.

Nylon's Flexibility

Now, let's talk about nylon. Is it stretchy? Absolutely! Nylon is one of those fabrics that combines strength with a remarkable ability to stretch. But how stretchy, you ask? Well, nylon can typically stretch up to 33% of its length and still return to its original form. Pretty impressive, right?

The secret behind nylon's flexibility lies in its molecular structure. Remember those long chains of molecules we talked about? They are arranged in a way that allows them to move apart under stress and then snap back into place, like tiny elastic bands at a microscopic level.

2. Measuring and Comparing Nylon's Elasticity

When it comes to measuring elasticity, it's all about how much force you need to stretch the fabric and how well it returns to its original shape. Nylon scores high on both counts. Compared to fabrics like polyester or cotton, nylon offers a more significant stretch and better recovery.

Applications Benefiting from Nylon's Stretchiness

This stretchiness isn't just for show; it's incredibly useful. Think about where you need that perfect blend of strength and flexibility – athletic wear, swimwear, hosiery, and adventure gear like parachutes and ropes. Nylon's ability to stretch under pressure and bounce back makes it the go-to fabric for these applications.

In our next sections, we'll explore more fascinating aspects of nylon. From how to take care of this wonder fabric to its myriad of uses, we're just getting started on our nylon journey. Stay tuned, and let's keep unraveling the nylon thread together! 🧵🏃♀️💪

📷 Credit: Ripstop by the Roll's Youtube Channel

X. How to Care for Nylon?

Alright, let's roll up our sleeves and talk about taking care of our nylon buddies. Nylon might be tough, but like a cactus in the desert, it still needs a bit of TLC to keep looking its best.

1. How to Clean Nylon?

- Check the Label: The care label is your roadmap to maintaining nylon's integrity. It contains crucial information about temperature limits, washing methods, and drying techniques. Think of it as the 'Instruction Manual' in the universe of nylon care.

- Cold Water is Your Friend: Using cold water is essential for nylon care. It prevents the material from becoming a shrinkage victim or losing its shape. Hot water can be harsh on nylon, leading to warping or weakening of fibers

- Gentle Cycle is the Way: Opt for a gentle or delicate cycle on your washing machine. Nylon may be a tough guy in the world of fabrics, but it appreciates a soft touch during cleaning. Aggressive spinning or vigorous cycles can cause unnecessary stress on the fabric.

- Mild Detergent for the Win: Go for a mild, gentle detergent. Harsh chemicals can be aggressive on nylon, breaking down its structure and fading its colors. A mild detergent ensures that the fabric retains its qualities without getting damaged.

- Air-Drying is Key: Always air-dry nylon. Exposing it to the high heat of a dryer can spell disaster. Instead, lay it flat or hang it out to dry. This method ensures that nylon retains its shape and size, prolonging its life.

Do's and Don'ts of Nylon Care

Do's

-

Prompt Stain Treatment: Act quickly on stains. Nylon's texture can hold onto stains, making them harder to remove over time. Gently dabbing the stain with a suitable cleaner can save the day.

-

Wash with Similar Fabrics: It's best to wash nylon with similar materials. Mixing it with harsher fabrics can lead to abrasion and wear.

Don'ts

-

Avoid Bleach: Never use bleach on nylon. It can degrade the fibers and ruin the color. Bleach is essentially the archenemy of nylon's wellbeing.

-

Prevent Overstuffing the Washer: Give your nylon items enough room to move freely in the wash. Overcrowding can lead to uneven washing and potential damage to the fabric.

Additional Tips

- Hand Washing Option: If you're dealing with delicate nylon items, consider hand washing. This method allows for gentle, targeted cleaning, especially for items like lingerie or fine hosiery.

- Using Fabric Softeners: If you choose to use a fabric softener, opt for a gentle, eco-friendly option. This can keep the nylon soft without the harsh chemicals.

- Ironing Nylon: If you must iron nylon, use the lowest heat setting and preferably place a protective cloth between the iron and the nylon fabric to avoid melting or scorching.

2. How to Iron Nylon?

- Low Heat Setting is Crucial: When ironing nylon, the key is to keep the iron's temperature on the lowest setting. Nylon and high heat are not friends – too much heat can cause the fabric to melt or distort, leaving you with a bigger problem than wrinkles.

- The Role of a Pressing Cloth: Always use a pressing cloth as a protective layer between the nylon fabric and the iron. This could be a thin cotton cloth or a specific ironing cloth. It acts as a mediator, preventing direct contact and thereby protecting the nylon from potential heat damage.

- Steam as a Gentle Smoother: Utilize the steam feature on your iron if available. The gentle release of steam can help ease out wrinkles without the need for direct heat. Think of it as a soft touch approach to straightening out those creases.

Alternatives to Ironing Nylon

- Hanging as a Natural Solution: Sometimes, the simplest solutions are the most effective. Hanging your nylon garments can naturally help remove wrinkles, thanks to gravity's gentle pull. This method is especially effective for larger items like nylon jackets or pants.

- Leveraging Shower Steam: The shower steam method is a clever hack. While taking a hot shower, hang the nylon garment in the bathroom but not in the direct path of water. The steam from the shower creates a warm, humid environment that can help relax and release the wrinkles in the fabric. It's like giving your nylon garment a mini spa treatment.

Additional Tips for Ironing Nylon

- Ironing Nylon Mesh: If you're ironing more delicate nylon like mesh, extra caution is needed. The pressing cloth becomes even more important, and gentle tapping with the iron rather than gliding can prevent damage.

- Dealing with Stubborn Wrinkles: For tougher wrinkles, slightly dampen the pressing cloth. The moisture, combined with low heat, can provide just enough assistance to smooth out stubborn creases.

- Avoiding Direct Sunlight: After ironing, avoid laying the nylon garment in direct sunlight to dry. Direct sunlight can cause the colors to fade, especially after heat has been applied.

- Test on a Small Area: If unsure about the iron's heat or the fabric's reaction, always test on a small, inconspicuous area of the garment first. This precaution can save you from potential fabric damage.

3. How to Dye Nylon?

DIY Dyeing: Unleashing Your Creative Side

- Choosing the Right Dye: When it comes to DIY dyeing, nylon has a preference for acid dyes. These dyes are specially formulated for synthetic fibers and can create vibrant, long-lasting colors.

- Preparation is Key: Before you begin, ensure you have all the necessary materials: acid dye, a large pot for dyeing, protective gloves, and a stirrer.

- Safety First: Always dye in a well-ventilated area and wear protective gear like gloves and an apron to avoid staining your clothes or skin.

- Step-by-Step Process: Follow the dye's instructions carefully. Typically, this involves dissolving the dye in hot water, adding the nylon, and maintaining the right temperature for the dye to set.

- Experiment with Colors: Feel free to experiment with different colors. Nylon takes on dye very well, so it's a great opportunity to get creative with hues and shades.

Professional Dyeing: For Perfection Seekers

- Complex Projects: For intricate patterns or when you require a uniform, professional look, it's best to turn to professional dyeing services.

- Color Matching: Professionals can precisely match colors and ensure an even application, which is especially important for items like garments or upholstery.

Post-Dyeing Care: Preserving Your Masterpiece

- Rinse Thoroughly: After dyeing, it’s crucial to rinse the nylon item under cold water until the water runs clear. This step ensures that all excess dye is washed out, preventing future color bleeding.

- Wash Separately: For the first few wash cycles post-dyeing, wash the nylon item alone. This isolation prevents any residual dye from staining other clothes.

- Use Mild Detergent: When washing the newly dyed nylon, use a mild detergent and opt for a gentle wash cycle to preserve the color integrity.

- Temperature Matters: Always use cold or lukewarm water for these initial washes. Hot water can cause the dye to release and fade.

Additional Tips for Dyeing Nylon

- Testing First: If you're unsure about the color outcome, test the dye on a small, inconspicuous area of the nylon item first.

- Maintaining Color Vibrancy: To maintain the vibrancy of the dye, consider using a color-safe detergent in future washes.

- Avoiding Direct Sunlight: When drying dyed nylon, avoid direct sunlight as it can cause the color to fade prematurely.

- Ironing Dyed Nylon: If you need to iron the dyed nylon item, use a low heat setting and preferably iron on the reverse side or with a protective cloth to preserve the new color.

4. How to Repair Nylon?

Repairing nylon doesn't have to be a daunting task. Whether it's a small tear in your favorite jacket or a larger rip in your nylon backpack, there are several ways to fix it up and extend its life. Here's a more detailed look at how to handle nylon repairs:

Sewing Small Tears

- Gather the Right Tools: A sewing needle and nylon or polyester thread are your best friends here. Choose a thread color that matches your nylon item for a seamless look.

- Stitching Technique: Use a fine needle and a backstitch or whip stitch for durability. Be gentle to avoid further damage. If you're new to sewing, practicing on a scrap piece of nylon first can be helpful.

- Securing the Repair: Once you've sewn the tear, tie off the ends of the thread securely. A small dab of clear nail polish or fabric glue can prevent the knot from unraveling.

Patch It Up

- Selecting the Right Patch: Choose a nylon patch that closely matches the color and texture of your item. You can find pre-cut patches or cut a piece from a spare nylon fabric.

- Using Fabric Glue: Apply a fabric glue that's suitable for nylon. Spread it evenly on the patch and the area around the tear, then press the patch firmly in place.

- Reinforcing with Stitches: For added strength, especially on items that undergo a lot of wear and tear, you can stitch the edges of the patch after gluing.

- Curing Time: Allow the glue to dry completely, following the manufacturer's recommendations, before using the item again.

Professional Repair

- When to Seek Professional Help: If the damage is complex, such as a large rip in a critical area (like seams or zippers), or if the item is expensive and requires a meticulous touch, it's best to turn to a professional.

- Finding a Specialist: Look for a repair service that specializes in outdoor gear or nylon products. They will have the right tools and expertise to handle the repair without causing further damage.

- Considering Cost vs. Replacement: Evaluate the cost of professional repair against the item's value and the cost of replacement. Sometimes, investing in a repair can save you money in the long run and is more environmentally friendly.

Additional Tips

- Preventing Further Damage: When you first notice a tear, use a piece of tape to prevent it from getting bigger until you can repair it.

- Waterproofing the Repair: If the item needs to be waterproof, like a rain jacket or tent, consider applying a seam sealer to the repair area.

- Care Post-Repair: Once repaired, handle the item with care, especially in the area of the repair. Avoid putting extra stress on the mended part.

With these care tips, your nylon gear will be ready for whatever adventure (or laundry day) throws at it. Keep it clean, keep it cool, and keep it colorful! And remember, a little care goes a long way in the world of nylon. 🧵✨👚

XI. What is Nylon Used For?

Alright, let's talk about where nylon really shows off its versatility. You might be surprised at just how many places this wonder material pops up in our daily lives and beyond. From the soles of your sneakers to the airbags in cars, nylon is like that friend who's everywhere, doing everything!

1. Common Uses

First up, the everyday uses. Nylon has a knack for turning up in places you'd least expect. Here's a quick rundown:

- Clothing: Think durable, wrinkle-resistant garments. Nylon is a star in activewear, swimwear, and, of course, the classic nylon stockings.

- Home Goods: Ever lounged on a hammock? That's often nylon. It's also in your toothbrush bristles and the carpets under your feet.

- Industrial Applications: Nylon's strength and heat resistance make it ideal for automotive parts, machine gears, and conveyor belts.

- Outdoor Gear: Hikers, rejoice! Nylon's in your lightweight tents, backpacks, and ropes.

- Sports Equipment: Tennis rackets, basketball nets, and even the fabric in parachutes – nylon's got them covered.

And that's just scratching the surface.

Case Studies or Examples

- Fashion Industry: Take the iconic nylon Prada backpack that revolutionized high fashion in the 1980s. Durable, water-resistant, yet stylish - a perfect blend of form and function.

- Automotive Sector: In the world of cars, nylon helps lighten the load. It's used in engine components, replacing metal to improve fuel efficiency.

2. Specialty Uses

Now, let's step into the lesser-known realm of nylon applications. This is where things get really cool:

- Medical Field: Nylon's used in surgical sutures and orthopedic devices. It's strong, yet flexible – exactly what you need in the medical world.

- 3D Printing: As a printing material, nylon allows for the creation of intricate, durable objects, opening a world of possibilities in manufacturing and design.

Future Potential

Looking ahead, nylon's future is as bright as its past. Here's where it could shine next:

- Environmental Technology: Innovations in recycling processes could make nylon a key player in sustainable fashion and eco-friendly materials.

- Aerospace: Its strength-to-weight ratio makes it a candidate for various aerospace applications, potentially reducing the weight of aircraft and spacecraft.

Nylon isn't just a fabric; it's a groundbreaking material that's shaped and continues to shape multiple industries. Its versatility and adaptability make it a material well-suited for an ever-evolving world. Stay tuned to see where nylon heads next – the possibilities are as endless as the polymer chains it's made of! 🌍✈️🚀

Conclusion

The extraordinary journey of nylon, a material that's as much a part of our world as the air we breathe. From its humble beginnings in a lab to becoming a ubiquitous presence in our everyday lives and beyond, nylon has proven to be more than just a fabric; it's a symbol of human ingenuity and adaptability. Its ability to transform, adapt, and find new purposes is a testament to the endless potential of human innovation.

As we've explored, nylon's versatility makes it a hero in various sectors, from fashion to aerospace. It's not just about the clothes we wear or the gear we use; it's about a material that's been constantly evolving, pushing boundaries, and helping us reimagine what's possible. The story of nylon is far from over. With each passing day, new uses, innovations, and advancements are being discovered, ensuring that this remarkable material will continue to play a vital role in shaping our future.

Nylon may just be a series of molecular chains, but its impact is colossal, woven intricately into the fabric of our lives. So, the next time you zip up that nylon jacket or pack that durable backpack, remember the incredible journey of this extraordinary material.

FAQ

1. What distinguishes nylon from natural fibers?

Nylon stands apart from natural fibers due to its synthetic origin, giving it characteristics like remarkable durability, superior elasticity, and resistance to water, mildew, and abrasion. Unlike natural fibers such as cotton or wool, which are prone to wear and tear, nylon maintains its integrity over time, making it a go-to choice for long-lasting products.

2. Can nylon be recycled, and if so, how?

Yes, nylon can be and is increasingly being recycled. The recycling process typically involves depolymerization, where the nylon is broken down into its monomers. These monomers can then be purified and repolymerized to create new nylon fibers. This process not only reduces waste but also conserves the energy and raw materials needed to produce virgin nylon.

3. Is nylon a good choice for outdoor gear? Why or why not?

Nylon is an excellent choice for outdoor gear due to its unique combination of lightweight, durability, and water resistance. These properties make it ideal for items like tents, backpacks, and outdoor clothing. Nylon's ability to withstand various weather conditions without compromising its structural integrity is a key factor in its widespread use in outdoor applications.

4. How does the cost of nylon compare to other synthetic fabrics?

While nylon is generally more affordable than high-end synthetics, it can be more expensive than some other common synthetic materials due to its higher quality, durability, and the complex manufacturing processes involved. However, the cost is often justified by nylon's longevity and superior performance characteristics.

5. Can nylon cause allergies or skin irritation?

Generally, nylon is considered hypoallergenic and does not irritate the skin. However, some individuals may experience mild irritation, potentially due to additives or chemicals used during the manufacturing process, rather than the nylon itself. It's relatively rare but worth considering for those with sensitive skin.

6. How does UV exposure affect nylon products?

Continuous UV exposure can significantly impact nylon, leading to a reduction in its tensile strength and elasticity, as well as causing color fading. This degradation is due to UV rays breaking down the polymer chains in nylon. Protective coatings or treatments are often used to enhance nylon's UV resistance, especially for outdoor applications.

7. Are there biodegradable alternatives to nylon?

The search for biodegradable alternatives to nylon is an ongoing endeavor in the textile industry. Scientists are developing synthetic fibers that mimic nylon's properties but are made from renewable resources and can break down naturally over time. These developments are crucial in reducing the environmental impact of synthetic textiles.

8. Can nylon be blended with other fabrics, and what are the benefits?

Blending nylon with other fabrics can enhance its inherent properties and mitigate some of its limitations. For example, when combined with cotton, the blend benefits from cotton's breathability and nylon's durability. Similarly, adding spandex to nylon increases its stretchability. These blends result in textiles that are versatile, comfortable, and suitable for a wide range of uses.

9. How does nylon's performance compare in extreme temperatures?

Nylon is known for its ability to perform well under a variety of temperature conditions. It remains stable and maintains its strength in both cold and moderately high temperatures. However, at very high temperatures, nylon can start to weaken and melt. This characteristic necessitates careful consideration when using nylon in high-heat environments.

10. What are the latest innovations in nylon fabric technology?

Recent advancements in nylon technology focus on sustainability and performance enhancement. These include developing eco-friendly manufacturing processes that reduce water and energy usage, improving recycling methods to make nylon more circular in its life cycle, and engineering nylon fibers to have specific properties such as enhanced moisture-wicking or increased elasticity. These innovations are making nylon not only more versatile but also more aligned with environmental sustainability goals.

📫 Related Blog Posts:

📌 What Is Recycled Polyester ? A Journey From Bottle to Fabric

📌 What is Polyester Fabric? Everything You Need to Know

📌 What is Ripstop Fabric? The Unsung Hero of Durable Textiles

Leave a comment